District heating is a safe and reliable form of heating that provides resource efficient, low CO2-emitting solutions. It is often produced in combination with electricity, which reduces environmental impact.

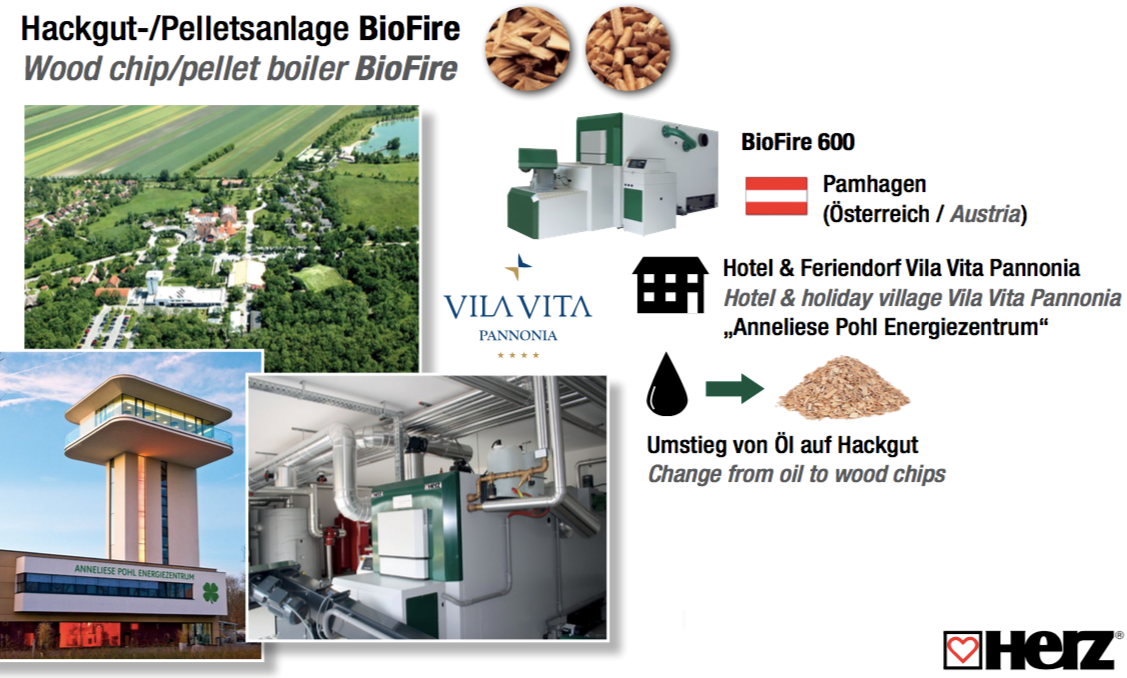

It has been around in Europe for more than 20 years and is now feasible in South Africa. Primarily in apartment blocks, hotels, and housing estates.

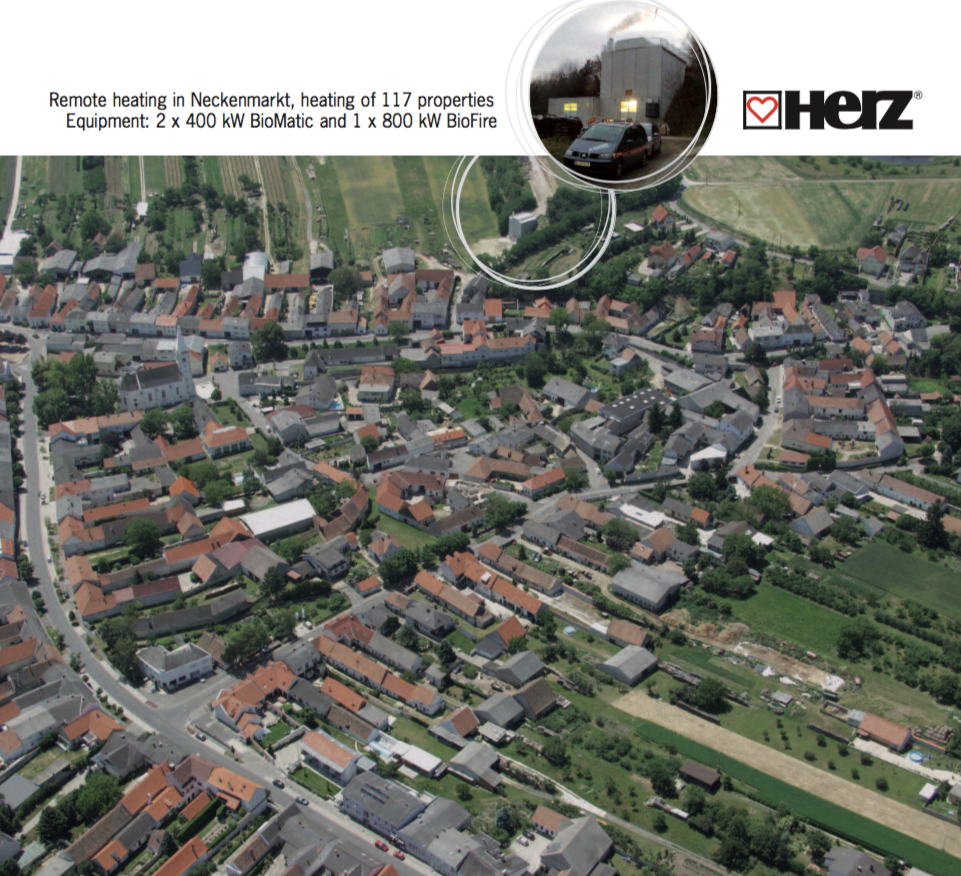

District heating is produced in one or several central production facilities and distributed to various buildings or apartment units through insulated pipes.

The picture below shows an actual district (177 Houses) in Austria that is supplied with all its hot water and space heating needs by the shed at the top middle of the picture.

Benefits of EcoSmart™ Biomass District Heating Systems:

- Low cost hot water and space heating: as little as 55 cents per kWh

- Lower installation and unit costs: Due to less units needed than a conventional heat pump system

- Large savings on electricity: our units use as little as 200 watts whilst operating and 60 watts in standby

- Smaller electrical connection needed for the entire development

- Heating no longer affected by Load shedding: due to the low electricity usage of the units they can easily connected to a battery backup or photovoltaic system to supply it with power when the nation energy provider cannot.

- Less heating units needed = lower cost: EcoSmart’s biomass units start from 10 kW and increase to 1500 kw, this means less units needed and lower maintenance costs.

- Easy monitoring and tenant billing for hot water and space heating used.

When district heating is combined with a renewable energy source (Biomass) the energy costs for the individual staying in the district are much lower as well as a reduced carbon footprint.

As water heating take up a large proportion of household heating, district heating will greatly lower electrical grid dependence.

Why Choose Biomass?

Carbon Neutral: Biomass Wood Pellets are a renewable green energy, and responsible biomass energy production is carbon neutral, according to UN COP 21 it reduces demand for fossil fuels, and incentivises forest growth. Also to be considered is that the waste material in the lumber process (sawdust, wood chips, wooden logs) will release the exact same amount of carbon into the atmosphere as when it is burned in a Herz biomass boiler as wood logs, wood chips or wood pellets.

As the pellets are produced from the offcuts and chips of sawmills and board manufacturers, it means that excess wood that cannot be used, is being put to good use and allowing for less wastage.

Reliable Supply:

Supply is no longer a problem in South Africa, as there are many operational pelletising plants around the country and many under construction.

Guaranteed electricity savings:

As the heating energy is extracted from the biomass pellets, the Biomass Boiler heats consistently in summer and winter, without the electrical consumption experienced by other heating methods.